The Impact of 3D Printing on Biomedical Engineering

In recent years, 3D printing has emerged as a revolutionary technology in many industries, and biomedical engineering is no exception. With its ability to create highly customized structures, 3D printing has unlocked new possibilities for designing medical devices, prosthetics, implants, and even human tissue. By enabling precise and efficient fabrication, this technology is transforming the way healthcare solutions are developed and delivered. In this article, we will explore the profound impact of 3D printing on biomedical engineering and the groundbreaking innovations it has introduced.

1. What Is 3D Printing in Biomedical Engineering?

3D printing, also known as additive manufacturing, is a process that creates three-dimensional objects by building them layer by layer from a digital model. In biomedical engineering, this technology is used to fabricate medical products, ranging from prosthetics to tissue scaffolds. The ability to design and print highly personalized medical solutions has made 3D printing an essential tool for engineers, doctors, and patients alike.

Some of the most prominent applications of 3D printing in biomedical engineering include:

- Prosthetics and Orthotics

- Medical Implants

- Tissue Engineering

- Surgical Models

By using biocompatible materials such as titanium, polymers, and even living cells, 3D printing has opened up a new realm of possibilities in patient-specific care.

2. Enhancing Prosthetics with 3D Printing

One of the most well-known applications of 3D printing in biomedical engineering is in the creation of custom prosthetics. Traditionally, prosthetic devices were made using standardized molds that could not always fit the unique shape and size of a patient’s body. 3D printing, however, allows for the creation of highly personalized prosthetics tailored specifically to the individual’s anatomy.

Custom Fit and Comfort

- Personalized Design: 3D scanning technology enables precise measurements of a patient’s residual limb, which are then used to design a prosthetic that fits perfectly. This personalization leads to better comfort and functionality.

- Cost-Effectiveness: Traditional prosthetics can be expensive due to the labor-intensive manufacturing process. 3D printing offers a more affordable alternative by simplifying production and reducing material waste.

Advanced Materials for Durability

- Lightweight and Strong Materials: 3D printing enables the use of lightweight yet durable materials like carbon fiber and titanium for prosthetics, providing strength without adding unnecessary weight.

- Improved Mobility: With 3D-printed prosthetics, users can enjoy greater freedom of movement and an enhanced quality of life.

3. Revolutionizing Medical Implants

Medical implants are essential for treating a variety of conditions, from joint replacements to dental implants. However, traditional implant manufacturing methods often involve long lead times and less-than-ideal customization. 3D printing addresses these issues by enabling faster, more precise production of implants designed specifically for a patient’s body.

Custom Implants for Better Fit

- Patient-Specific Solutions: By using 3D imaging and scanning technology, engineers can create implants that match the exact shape and size of a patient’s anatomical structure. This minimizes the risk of complications and ensures a better fit, leading to better outcomes.

- Complex Geometries: 3D printing allows for the production of complex shapes and structures that are difficult or impossible to create using traditional methods. This includes implants with features like porous surfaces, which can promote better integration with surrounding tissues.

Minimizing Rejection Rates

- Biocompatible Materials: 3D printing offers the ability to print medical implants using materials that are highly compatible with the human body. For example, titanium is commonly used for orthopedic implants, as it is lightweight, strong, and highly resistant to corrosion.

4. Tissue Engineering and Regenerative Medicine

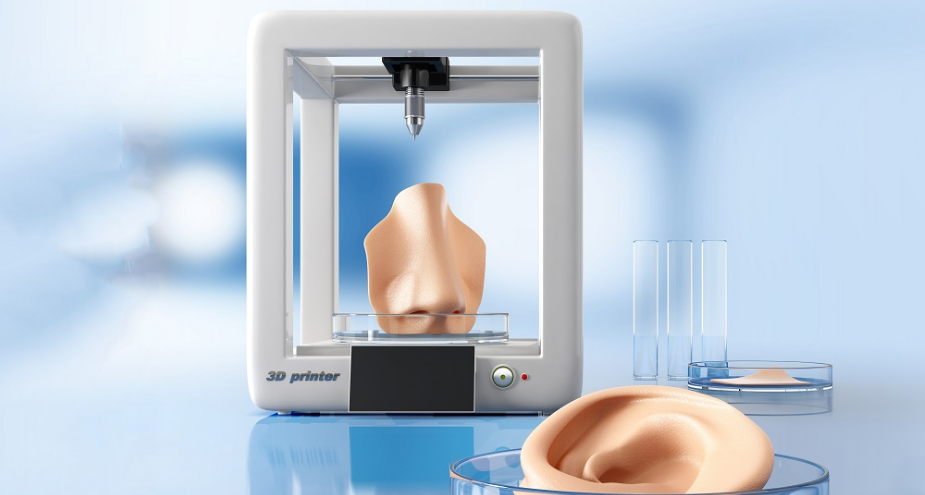

Perhaps one of the most exciting applications of 3D printing in biomedical engineering is in the field of tissue engineering and regenerative medicine. Researchers are using 3D printing to create scaffolds that can support the growth of new tissue, potentially leading to the regeneration of damaged organs and tissues.

Bioprinting: Printing Human Cells

- Living Tissue Creation: Bioprinting is a specialized form of 3D printing that involves printing living cells to create biomaterials and tissues. These tissues can be used in regenerative medicine, allowing scientists to explore the possibility of growing functional organs for transplantation.

- Organ Models for Research: Bioprinted tissues also serve as models for drug testing and disease research, offering a more accurate representation of human biology than traditional cell cultures or animal models.

Potential for Organ Regeneration

- Regenerating Damaged Tissues: While still in its early stages, 3D printing holds the potential to regenerate damaged tissues by printing scaffolds that encourage cells to grow and develop into fully functional tissues.

- Personalized Treatments: The ability to print tissue-specific structures opens up the possibility for personalized regenerative therapies, where patients can receive treatments that are tailored to their specific biological needs.

5. Surgical Models for Improved Precision

In addition to creating implants and prosthetics, 3D printing is increasingly being used to produce surgical models. These models are replicas of a patient’s anatomy, created from 3D imaging scans. Surgeons can use these models to plan and rehearse complex surgeries, improving their accuracy and reducing the risk of errors.

Pre-Surgical Planning

- Better Visualization: 3D-printed surgical models provide surgeons with a tangible, physical representation of a patient’s internal structures. This helps them plan surgeries more effectively and identify potential challenges before entering the operating room.

- Training and Education: These models also serve as valuable tools for medical education, allowing students and professionals to practice on realistic models before performing procedures on patients.

6. Ethical and Regulatory Considerations

As 3D printing continues to evolve in the biomedical field, ethical and regulatory considerations are becoming increasingly important. The ability to print biological tissues and medical implants raises questions about safety, efficacy, and the potential for misuse.

Safety Standards and Regulations

- FDA Approval: In the United States, medical products created with 3D printing must undergo rigorous testing and approval by the FDA (Food and Drug Administration) to ensure they meet safety standards. This includes testing for biocompatibility, durability, and overall performance.

- Ethical Concerns in Bioprinting: While the potential for printing human tissues and organs is exciting, it also raises ethical concerns about the use of human cells and the potential for creating genetically modified organisms.

Intellectual Property and Accessibility

- Intellectual Property Protection: As 3D printing becomes more prevalent in healthcare, protecting intellectual property and ensuring that innovations are properly licensed will be crucial to foster continued progress in the field.

- Access to Technology: The cost and availability of 3D printing technology may pose challenges for some regions, limiting access to cutting-edge healthcare solutions.

7. Conclusion: A Transformative Future for Biomedical Engineering

The impact of 3D printing on biomedical engineering is nothing short of transformative. From custom prosthetics to the development of functional tissues, 3D printing has already begun to revolutionize the medical field by enabling highly personalized, efficient, and cost-effective solutions. As technology continues to advance, the possibilities for 3D printing in biomedical engineering are virtually limitless, and the future of healthcare will undoubtedly be shaped by these innovations.

By overcoming engineering challenges and addressing ethical concerns, 3D printing will continue to push the boundaries of medical treatments, bringing us closer to a future where regenerative medicine, personalized healthcare, and life-saving innovations are more accessible than ever before.

Also Read :

- Autonomous Vehicles: The Engineering Challenges and Innovations

- Sustainable Urban Planning: Engineering for Smart Cities

- How Quantum Computing is Shaping Modern Engineering

- The Cutting Edge: How is Shaping Tomorrow’s Engineering

- Engineering the Future: Insights from Our Research on agriculture catastrophe