Developing a Low-Cost Prosthetic Hand for Amputees

Developing a low-cost prosthetic hand is a meaningful project that combines engineering, design, and medical knowledge to improve the lives of amputees. This guide outlines the steps to create an affordable and functional prosthetic hand.

Key Components and Materials

- Microcontroller: Arduino Nano or ESP32 for controlling the hand.

- Servo Motors: Small servos for finger movement.

- Sensors:

- EMG (Electromyography) sensor for muscle signal detection.

- Force sensors for grip control.

- Frame Material: Lightweight and durable materials such as PLA (3D-printed), aluminum, or ABS plastic.

- Tendons: Fishing line or nylon threads for finger actuation.

- Power Source: Rechargeable Li-ion or Li-Po battery.

- Connectors and Wires: For connecting components.

- Glove or Skin Cover: Silicone or fabric for aesthetics and comfort.

Step-by-Step Instructions

- Plan the Design

- Sketch a design with realistic hand proportions.

- Decide on the number of degrees of freedom (e.g., independent finger movement).

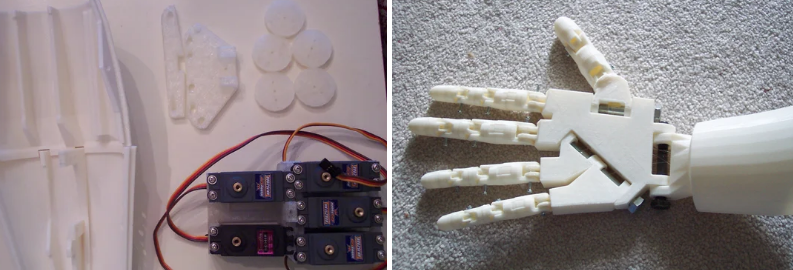

- Build the Frame

- Use a 3D printer or other methods to create the hand structure.

- Ensure joints are flexible and robust to support repeated movement.

- Install Motors and Tendons

- Attach servo motors to the base of the hand.

- Connect tendons from the motors to the fingers, ensuring smooth movement.

- Incorporate Sensors

- Place the EMG sensor on the forearm to detect muscle signals.

- Connect force sensors to the fingertips for grip strength measurement.

- Program the Microcontroller

- Write code to process signals from the EMG sensor.

- Map muscle signals to specific finger movements using PWM (Pulse Width Modulation) for servo control.

- Calibrate the force sensors for feedback and precise gripping.

- Power the System

- Connect the battery to the microcontroller and servos.

- Ensure sufficient power delivery without overheating components.

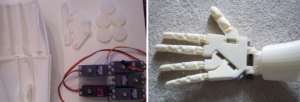

- Assemble and Test

- Combine all components and test individual functions.

- Adjust the tendons and sensor sensitivity for optimal performance.

- Optimize the Design

- Fine-tune the grip strength and range of motion.

- Add padding or a glove for comfort and realism.

Challenges and Troubleshooting

- Signal Noise: Use filters to eliminate noise in EMG readings.

- Power Constraints: Use a battery with sufficient capacity for prolonged use.

- Mechanical Wear: Regularly inspect and replace worn tendons or motor components.

Additional Features

- Bluetooth Connectivity: Enable remote control or customization via a smartphone app.

- Adaptive Grip: Use machine learning to adapt to different objects and tasks.

- Waterproofing: Incorporate waterproof materials for durability in various conditions.

Safety and Maintenance Tips

- Use insulated wires to prevent short circuits.

- Avoid overloading the motors to prolong their lifespan.

- Conduct regular maintenance to ensure reliable performance.

Conclusion

Developing a low-cost prosthetic hand provides an opportunity to make a positive impact on the lives of amputees. By focusing on affordability, functionality, and user comfort, this project can contribute to more accessible prosthetic solutions worldwide. With advancements in technology, such designs can be further refined for greater efficiency and adaptability.

Also Read :