As the world transitions toward cleaner and more sustainable energy, Small Modular Reactors (SMRs) are emerging as a transformative force in nuclear power. Unlike traditional nuclear plants, SMRs are compact, flexible, and engineered for enhanced safety and efficiency. These reactors represent a new era in nuclear engineering, combining advanced technology with innovative project design to meet the energy needs of the 21st century.

This article explores the engineering behind SMR projects, their global impact, and how they are shaping the future of nuclear energy.

What Are Small Modular Reactors (SMRs)?

Small Modular Reactors are compact nuclear reactors designed to generate up to 300 MW of electricity per module. Unlike conventional reactors, SMRs are built with modularity in mind, allowing factory construction, rapid deployment, and scalability according to demand.

Key features of SMRs include:

- Factory-Built Modules: Reducing construction time and costs.

- Passive Safety Systems: Reactors designed to cool themselves naturally in emergencies.

- Flexible Applications: Suitable for remote communities, industrial plants, or urban areas.

- Lower Capital Investment: Making nuclear power more accessible to diverse regions.

SMRs are not just smaller reactors—they are a reimagining of nuclear engineering principles to align with modern energy challenges.

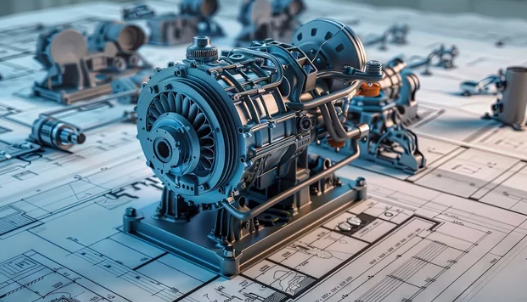

Engineering Innovations in SMR Design

SMR projects leverage a range of engineering innovations to ensure safety, efficiency, and adaptability:

Modular Construction

- Factory-built modules allow for streamlined assembly at the site, reducing delays and construction errors.

- Standardized designs enable economies of scale and cost predictability.

Advanced Safety Systems

- Passive cooling and emergency shutdown systems minimize the risk of meltdown.

- Multiple containment barriers ensure environmental protection even under extreme scenarios.

Digital Integration

- AI monitoring and control systems optimize reactor performance.

- Digital twins simulate reactor operations, allowing engineers to preemptively identify potential issues.

Fuel Efficiency and Waste Reduction

- SMRs often use advanced fuel cycles, improving efficiency and reducing radioactive waste compared to traditional reactors.

Leading SMR Projects Around the World

Several SMR projects are setting benchmarks for the nuclear industry:

NuScale Power (USA)

- First SMR design approved by U.S. regulators.

- Each module produces 77 MW, scalable up to 462 MW using multiple units.

- Focused on safety, modularity, and cost-efficiency.

Rolls-Royce SMR (UK)

- Aiming to deploy compact reactors for flexible energy generation.

- Designed for rapid factory assembly and reduced construction timelines.

- Potential to supply both electricity and industrial heat for manufacturing.

Canadian SMR Program

- Targeting remote communities and heavy industries.

- Emphasizes clean energy for areas lacking grid infrastructure.

- Collaboration between government, industry, and engineering firms to streamline deployment.

China’s ACP100 and HTR-PM Projects

- ACP100: A modular pressurized water reactor designed for coastal and inland applications.

- HTR-PM: High-temperature gas-cooled SMR providing both electricity and industrial heat.

Benefits of SMRs Over Traditional Nuclear Plants

SMRs offer several advantages that make them an appealing choice for the modern energy landscape:

- Scalability: Modules can be added as demand grows, avoiding overbuilding.

- Lower Financial Risk: Smaller upfront investment compared to gigawatt-scale plants.

- Enhanced Safety: Passive cooling systems reduce the risk of accidents.

- Versatility: Suitable for electricity, district heating, desalination, and hydrogen production.

- Rapid Deployment: Modular construction reduces project timelines from a decade to 4–6 years.

These benefits position SMRs as key players in achieving carbon-neutral energy goals worldwide.

Challenges and Engineering Solutions

Despite their promise, SMRs face engineering and regulatory challenges:

- Licensing and Regulation: SMRs require updated safety standards tailored to modular designs.

- Supply Chain Development: Mass production of reactor modules demands robust manufacturing infrastructure.

- Public Perception: Engineers must address safety concerns and communicate effectively with communities.

Innovations in digital monitoring, standardized designs, and advanced safety systems are helping overcome these hurdles.

The Future of SMR Engineering

The next decade could see SMRs deployed on a global scale, transforming energy systems:

- Remote and Island Communities: Providing reliable, carbon-free energy.

- Industrial Applications: Supplying electricity and process heat for manufacturing and mining.

- Hybrid Energy Systems: Integrating SMRs with renewables to provide stable baseload power.

- Global Export Opportunities: Countries with SMR expertise may supply reactors worldwide, creating a new international market for nuclear technology.

SMRs are a prime example of engineering innovation driving sustainable energy solutions.

Conclusion

The Small Modular Reactor revolution is more than a technological upgrade—it is a paradigm shift in nuclear engineering. By combining modular construction, advanced safety systems, and digital integration, SMRs make nuclear energy more accessible, flexible, and efficient.

As projects like NuScale, Rolls-Royce SMRs, and China’s HTR-PM come online, the world will witness a new era where nuclear power supports clean energy goals, industrial growth, and energy security. SMRs demonstrate how engineering innovation can harness the atom safely and effectively, providing a blueprint for the future of sustainable nuclear power.

Also Read :